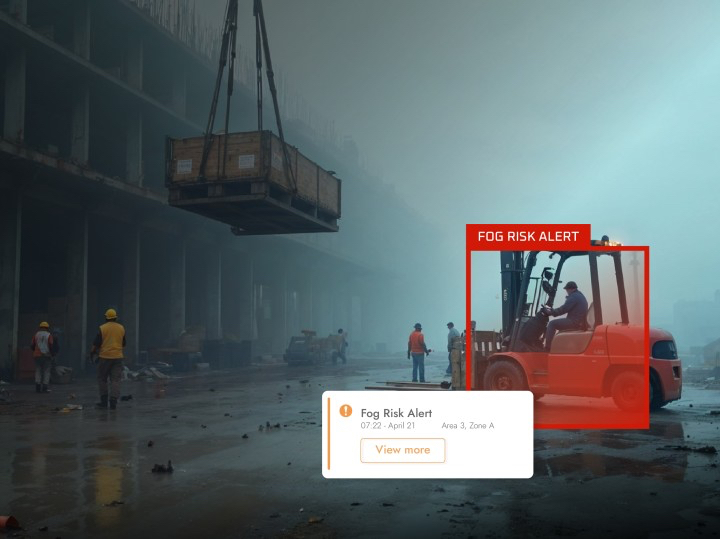

A Forklift, a Ladder and a Gut Feeling: What Almost Went Wrong?

It’s 6:52 AM on a foggy construction site. A forklift veers a little too close to an elevated platform. The supervisor makes a mental note –“Keep an eye on that corner.” But by then, the “almost accident” has already happened.

Now let’s flip the situation by using a smart safety management system to alert the EHS teams before the forklift gets there. The area is already flagged as high-risk based on previous near-misses, fatigue data, and behavioral trends.

That’s the power of Predictive AI in workplace safety.

From guessing games to algorithmic intuition

At a mining operation in Southeast Asia, predictive AI helped reduce near misses by 27% in just three months. Meanwhile, an offshore oil platform battling recurring process breakdowns used AI-powered incident management software to cut its Total Recordable Incident Rate (TRIR) by 40% in a year.

For decades, safety systems have been reactive – waiting for a problem to surface before springing into action. Predictive AI alters this model. The use of advanced AI tools, such as vision AI, AI video analytics, and generative AI now analyzes live and historical data to catch patterns invisible to the human eye.

These numbers tell a simple story: real-time prevention works better than post-incident response.

As Gary Ng, CEO of viAct puts it, “The best safety system is the one that thinks ahead and with predictive AI, it doesn’t wait for failure. It anticipates it.”

These numbers tell a simple story: real-time prevention works better than post-incident response.

As Gary Ng, CEO of viAct puts it, “The best safety system is the one that thinks ahead and with predictive AI, it doesn’t wait for failure. It anticipates it.”

AI That Reads Behaviors Like a Safety Psychologist

It’s no longer about watching every corner in a heavy industry worksite — it’s about understanding it. AI doesn’t just raise alarms, it interprets unsafe worker behavior.

In one Middle Eastern construction project, predictive systems integrated within a behavior-based safety software flagged a pattern of workers bypassing designated walkways to save time during peak hours. This risky shortcut, repeated by a small subcontractor crew, increased their exposure to heavy equipment zones.

Rather than waiting for a collision or close call, the EHS manager stepping with targeted safety coaching using the conversational AI chatbot and subtle workflow redesign.

Unsafe crossings dropped 63%, and more important, the accident that never happened was the one that mattered most.

Safety Metrics Rewritten by Machines

When predictive AI in workplace safety joins the team, the scoreboard changes. For instance, manufacturing companies that rely on predictive insights have reported a 35% drop in Days Away, Restricted, or Transferred (DART) scores. Lost Time Injuries (LTIs) are down by as much as 42% in operations where provisions such as ergonomic monitoring anticipate strain and respond to it in a timely manner.

Most crucially, Serious Injuries and Fatalities (SIFs), both real and potential are starting to disappear from the radar entirely, not because risk vanished, but because it was spotted early enough to be neutralized.

These aren’t just improved numbers; they’re stories of prevented tragedies, of time and talent not lost to avoidable incidents.

“With predictive AI in workplace safety, we’re not just reacting anymore – we’re pre-empting,” says Hugo Cheuk, COO of viAct.

Zero-Incident doesn’t have to be a dream, it can be a data-driven goal.

For years, “zero incidents” has been more of a motto for high-risk industries than a milestone. But with predictive AI, that goal is no longer symbolic – it’s tactical. AI is transforming site culture from reactive rule-following to proactive risk aversion.

Using predictive AI, workers trust their environment more, managers spend less time on incident reports and more time building safety into the system itself.

While AI doesn’t replace human judgment, it can sharpen it. In the pursuit of zero-incident workplaces, it’s a competitive edge industrial leaders can now implement to improve the workplace safety on their sites.

For decades, safety systems have been reactive – waiting for a problem to surface before springing into action. Predictive AI alters this model. The use of advanced AI tools like vision AI, AI video analytics, and Generative AI now analyzes live and historical data to catch patterns invisible to the human eye.

These numbers tell a simple story: real-time prevention works better than post-incident response.

As Gary Ng, CEO of viAct puts it, “The best safety system is the one that thinks ahead and with predictive AI, it doesn’t wait for failure. It anticipates it.”

AI That Reads Behaviors Like a Safety Psychologist

It’s no longer about watching every corner in a heavy industry worksite – it’s about understanding it. AI doesn’t just raise alarms, it interprets unsafe worker behavior.

In one Middle Eastern construction project, predictive systems integrated within a behavior-based safety software flagged a pattern of workers bypassing designated walkways to save time during peak hours. This risky shortcut, repeated by a small subcontractor crew, increased their exposure to heavy equipment zones.

Rather than waiting for a collision or close call, the EHS manager stepping with targeted safety coaching using the conversational AI chatbot and subtle workflow redesign.

Unsafe crossings dropped 63%, and more important, the accident that never happened was the one that mattered most.

Safety Metrics Rewritten by Machines

When predictive AI in workplace safety joins the team, the scoreboard changes. For instance, manufacturing companies that rely on predictive insights have reported a 35% drop in Days Away, Restricted, or Transferred (DART) scores. Lost Time Injuries (LTIs) are down by as much as 42% in operations where provisions such as ergonomic monitoring anticipate strain and respond to it in a timely manner.

Most crucially, Serious Injuries and Fatalities (SIFs), both real and potential are starting to disappear from the radar entirely, not because risk vanished, but because it was spotted early enough to be neutralized.

These aren’t just improved numbers; they’re stories of prevented tragedies, of time and talent not lost to avoidable incidents.

“With predictive AI in workplace safety, we’re not just reacting anymore—we’re pre-empting,” says Hugo Cheuk, COO of viAct.

Zero-Incident doesn’t have to be a dream, it can be a data-driven goal.

For years, “zero incidents” has been more of a motto for high-risk industries than a milestone. But with predictive AI, that goal is no longer symbolic – it’s tactical. AI is transforming site culture from reactive rule-following to proactive risk aversion.

Using predictive AI, workers trust their environment more, managers spend less time on incident reports and more time building safety into the system itself.

While AI doesn’t replace human judgment, it can sharpen it. In the pursuit of zero-incident workplaces, it’s a competitive edge industrial leaders can now implement to improve the workplace safety on their sites.

Top 3 Takeaways:

– AI workplace safety software can flag potentially unsafe work environments based on conditions on the ground, previous similar situations which resulted in workplace safety hazards.

– AI workplace safety software can predict hazardous situations before they become troublesome.

– AI workplace safety software doesn’t replace human judgment, it augments it.

Keywords: AI Today, AI, artificial intelligence, workplace safety, viACT